HEM-Summary

Multi-turn electric actuator

Available torque range from 60N.M to 3000N.m.

Available speed range from 18rpm to 144rpm.

Designs and controls with basic,intelligent,fieldbus and separated control box to select.

IP67 enclosure protection as standard,IP68,BT4/BT6,CT4/CT6 as options.

Suitable for ball valve,butterfly valve,plug valve,gate valve,globe valve,check valve and regulating valve.

HEM-Advantages

Advance technology

Reliable operation

Heavy duty motor

Accurate torque measure

Continuous position tracking

Real time valve and actuator performance information

Auto self test and diagnosis

Versatile enclosure

Easy maintenance

Hardwired controls and fieldbus communication options.

Asset management

Non intrusive setting

Command/Mode selector switch for remote or local control

Infrared remote control to set and commissioning

Valve and Actuator Protection

Phase monitoring

Protection of change in direction

Motor thermal protection

Torque protection

Emergency shutdown protection

Failure monitor relay

Password protection

Failure Alarms indication

User friendly &intuitive controls

High resolution LCD display(except for basic type)

Local signal

Local commands

User friendly menu

Specificities

1.Double sealing

Two o-rings insure an optimum protection against water ingress into the electrical compartment based on GB/T4942.2-93,IP68 as option.

2.Non intrusive setting

Open/Close/Stop button and LOC/OFF/REM selector switch to achieve the close and open operation at site.

The infrared remote control to set and commissoning the data.

3.Rotatable electrical compartment and LCD display.

Possible to rotate the electrical compartment with LCD display to suit the actuator mounting.

Possible to rotate the direction of cable entries to meet the wiring requests.

The high resolution display has a wide view making it legible from a distance.

4.Heavy duty motor

Squirrel cage motor with built-in 135℃ thermostat protection,low inertia design,Class F insulated.

5.Position measure

Absolute position encoder output the accurate position to show on LCD,there is no position loss due to mains power loss or any interferences.

6.Torque sensor

The torque sensor directly measures output torque and converts value to a voltage signal.Torque of intelligent type can be set in the range 40% to 100% of rated torque with the additional facility to bypass torque switch.

7.Drive train

The drive train uses the basic design with the features of simple,reliable and robust, the components are oil lubricated with maintenance-free.

8.Explosion proof enclosure as option

In accordance with ExdIICT4,atmospheric pressure range from 86Kpa to 106Kpa,ambient temperature range from-30℃ to 60℃.

ExdIIBT4,ExdIIBT6,ExdIICT6 as options.

9.Handwheel and Declutch button

Push the red declutch button to achieve the handwheel operation when emergency or commissioning.

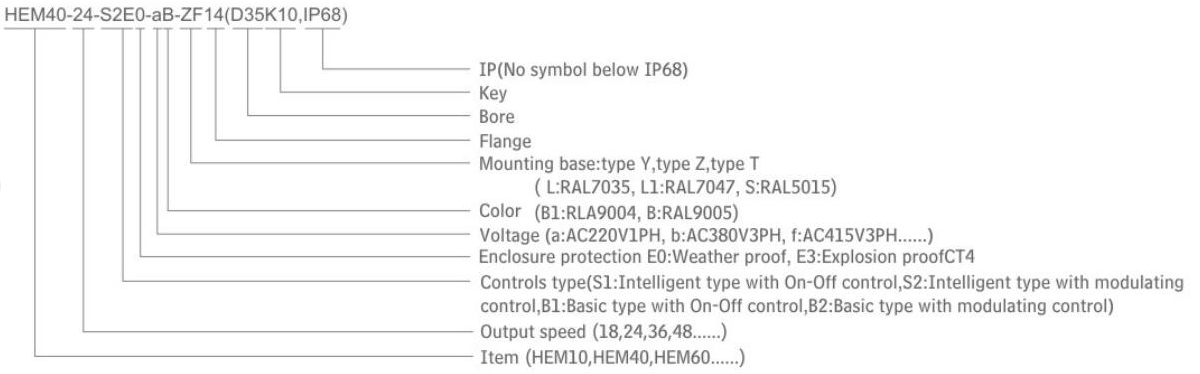

Model meaning