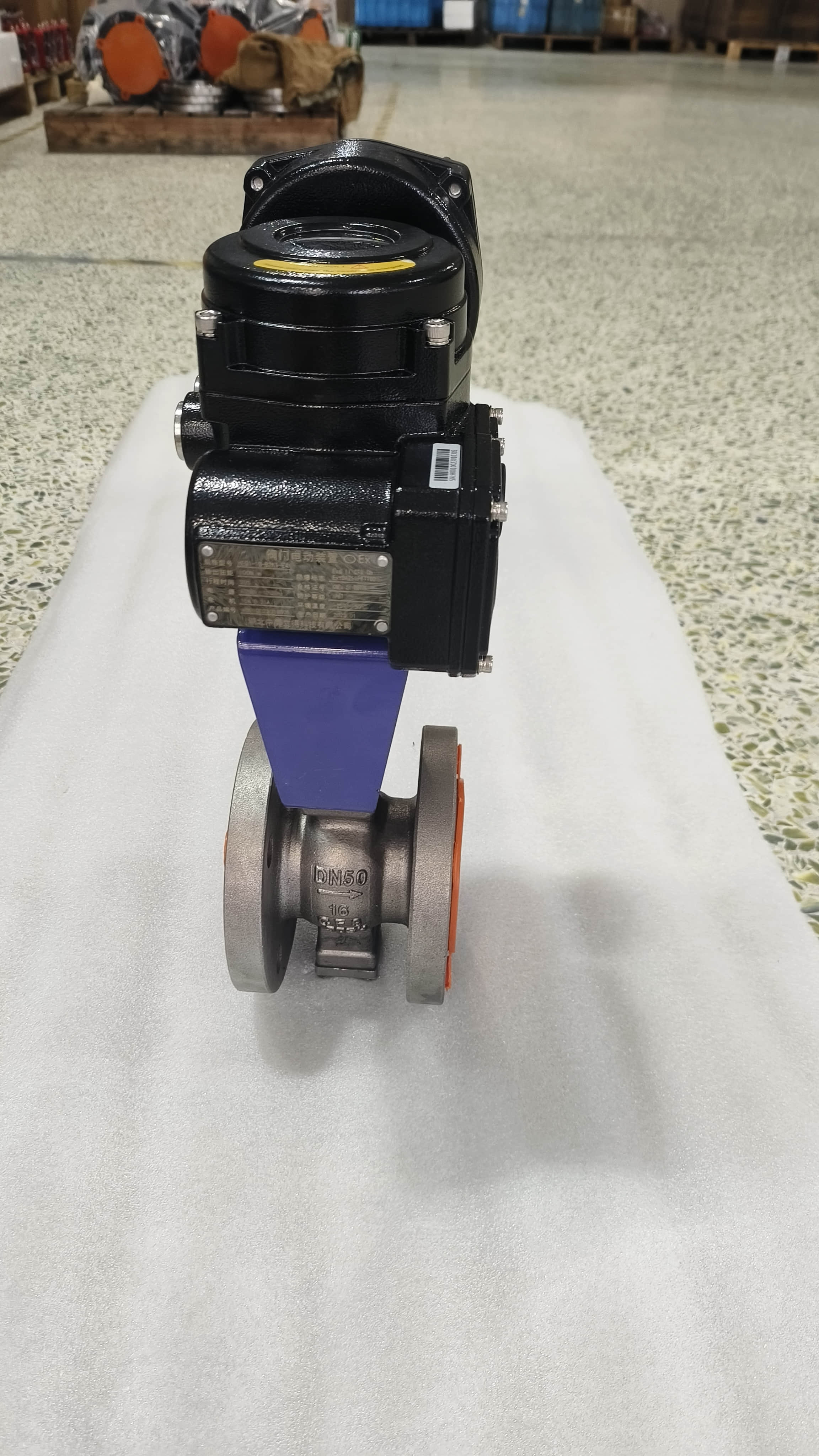

In today's industrial landscape, safety and efficiency are paramount. Among the critical components that ensure these factors in fluid control systems are explosion-proof electric ball valves. These valves are specifically designed to operate in hazardous environments, where the risk of explosions due to flammable gases or liquids is prevalent. The growing demand for reliable and safe solutions in industries such as oil and gas, chemicals, and pharmaceuticals has led to the rise of specialized manufacturers focusing on explosion-proof electric ball valves.

Explosion-proof electric ball valves are constructed to prevent ignition sources from entering their mechanisms. They feature robust materials that can withstand extreme conditions, ensuring their longevity and reliability. The design of these valves typically includes fail-safe features, which enhance operational safety. Manufacturers are increasingly employing advanced materials like stainless steel and high-performance polymers to enhance durability and corrosion resistance. This innovation not only improves the lifespan of the valves but also reduces maintenance costs for operators.