In the evolving landscape of industrial automation, electric globe valve manufacturers have become pivotal players in driving efficiency and precision. These manufacturers produce sophisticated valves designed to control the flow of fluids within various systems, from water treatment plants to complex manufacturing processes. By integrating electric actuators with traditional globe valve designs, these manufacturers offer advanced solutions that significantly enhance operational reliability and performance.

Electric globe valves are engineered to provide precise control over the flow of fluids, which is crucial for maintaining system stability and efficiency. Unlike their manual counterparts, which require physical effort to adjust, electric globe valves can be operated remotely and automatically, offering seamless integration into automated systems. This remote control capability is especially valuable in settings where manual operation is impractical or unsafe, such as in hazardous environments or high-pressure systems.

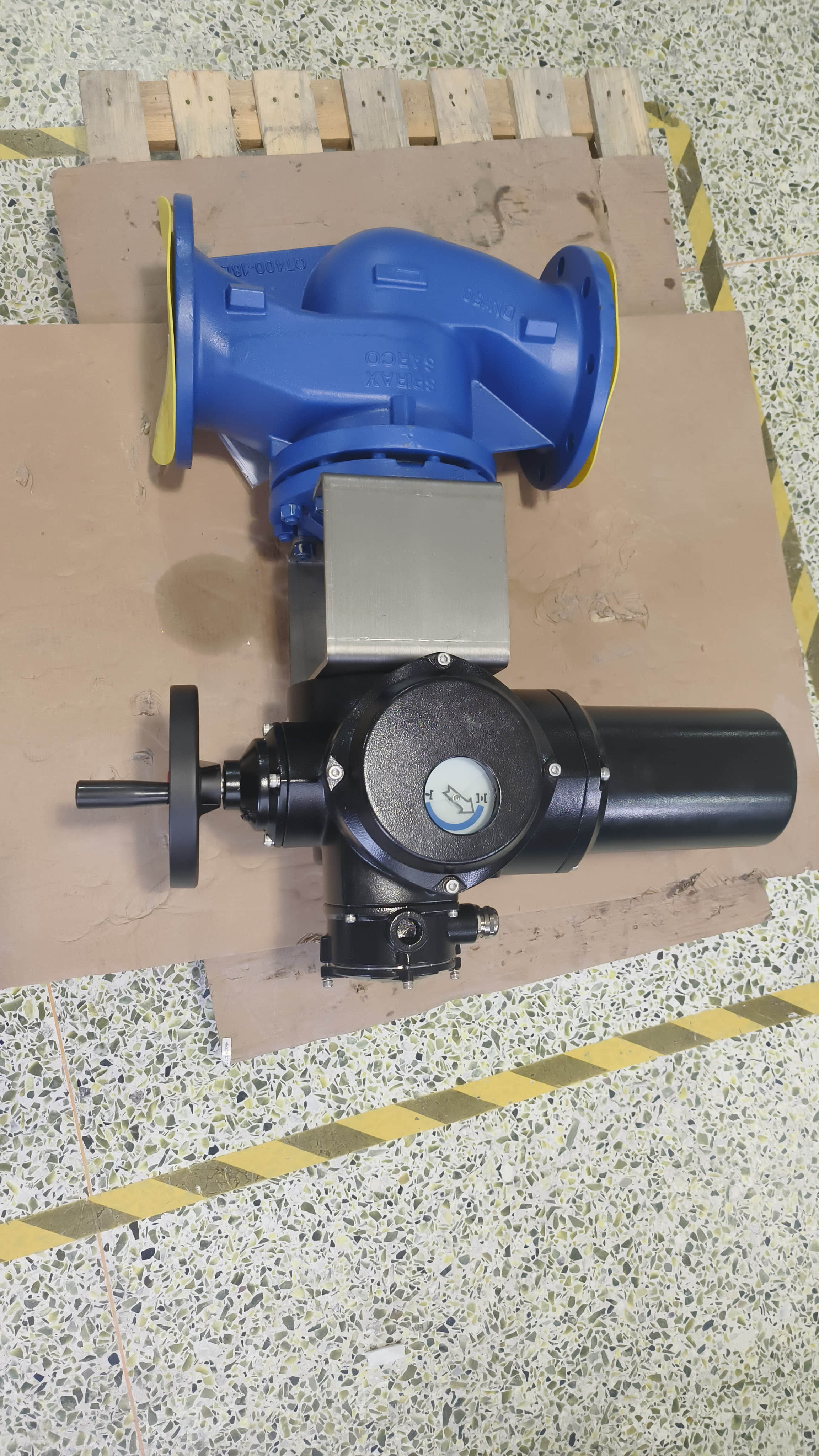

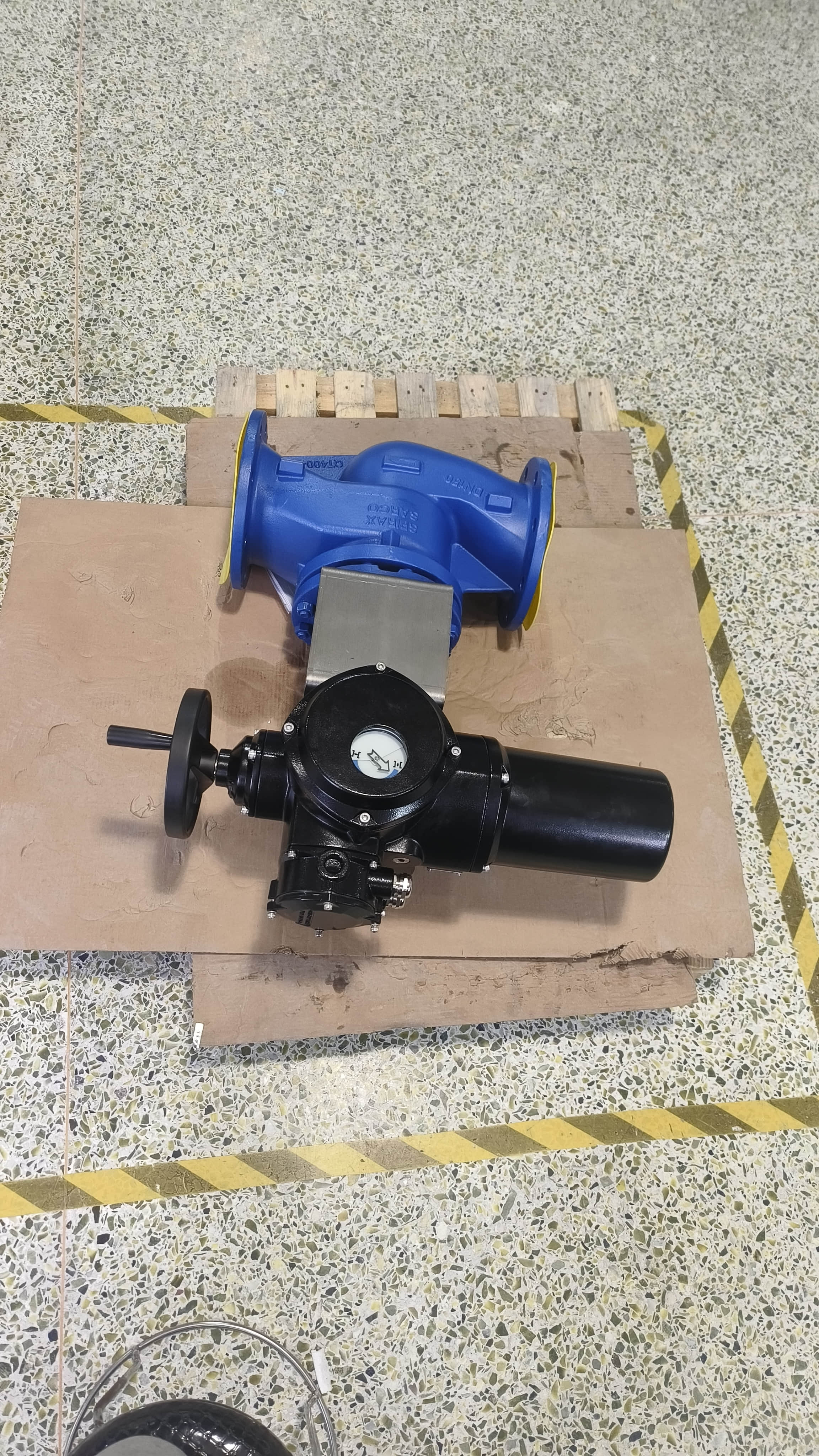

The manufacturing process for electric globe valves involves sophisticated technology and high-quality materials. Manufacturers often utilize advanced machining techniques and stringent quality control measures to ensure that each valve meets industry standards. Materials like stainless steel, bronze, and high-grade alloys are commonly used to withstand extreme temperatures and corrosive environments. Additionally, electric actuators are designed to provide smooth and reliable operation, with features such as adjustable stroke limits and feedback sensors that enhance the valve's performance and longevity.